Machine Learning Accelerates High-Resolution 3D Printing: A Breakthrough in Melt Electrowriting Technology

Queensland University of Technology (QUT) researchers have unveiled a transformative method for advancing melt electrowriting (MEW), a cutting-edge high-resolution 3D printing technology. Widely applicable in tissue engineering, regenerative medicine, and other fields like soft robotics, MEW’s progress has historically been hindered by long experimental timelines, slow printing speeds, and inconsistent results.

How Machine Learning Revolutionizes MEW

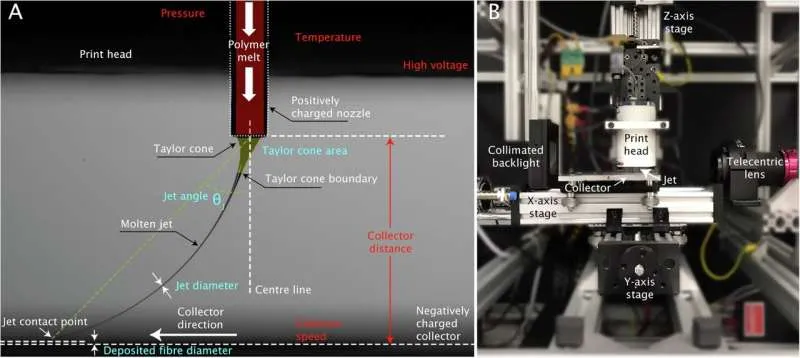

Dr. Pawel Mieszczanek, the study’s first author, highlighted how machine learning (ML) has been integrated into MEW to overcome these barriers. The research introduced a closed-loop process control system, which employs real-time imaging to monitor and adjust the fiber-flight path continuously. This innovative approach improves operational efficiency and consistency in MEW output.

- Faster Experimentation: The automated system drastically reduces experimental time from weeks to hours.

- Enhanced Accuracy: Real-time data collection ensures precision and reliability.

- Advanced Algorithms: A feedforward neural network combined with optimization techniques ensures reproducible and high-quality printed parts.

Impact on Industry and Research

Distinguished Professor Dietmar W. Hutmacher emphasized the broader implications of this advancement, calling it a significant step toward industry-ready additive manufacturing. The automated nature of this system enhances productivity and opens new avenues for biomedical and materials science applications.

Research Collaboration and Publication

The interdisciplinary team behind the breakthrough includes experts from QUT and the University of Oregon. Their study, titled “Towards Industry-Ready Additive Manufacturing: AI-Enabled Closed-Loop Control for 3D Melt Electrowriting,” was published in Communications Engineering.

This development marks a milestone in the convergence of machine learning and 3D printing, showcasing the potential for technology to redefine the boundaries of precision manufacturing.